Wind tunnel

close type

A large group of the CTO S.A. offer are closed-circuit wind tunnels.

Each tunnel is designed to meet your specific needs.

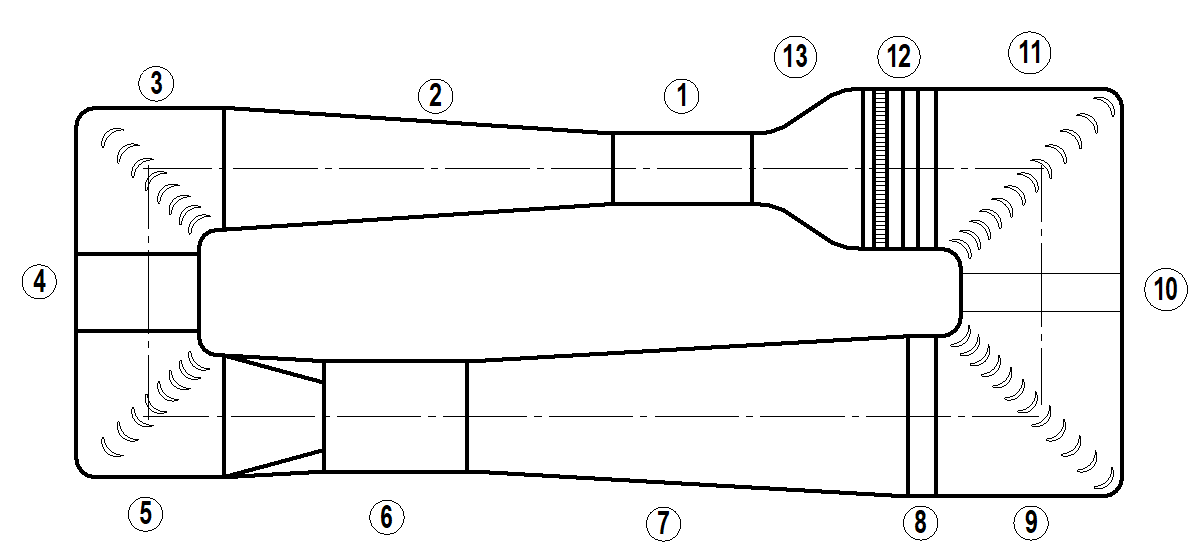

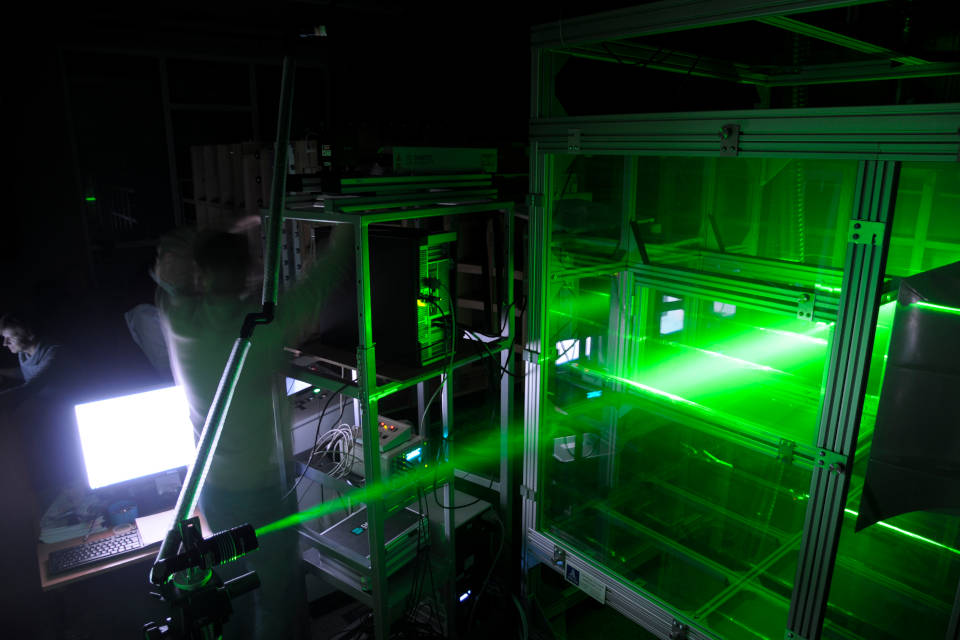

In closed-type wind tunnels, a gradually expanding diffuser guides the air back into the contraction so that the air constantly circulates in a closed loop. Typical closed-loop tunnels with open and closed test sections are shown in the figures below.

| Item | Section name |

|---|---|

| 1 | Test section |

| 2 | Diffuser I |

| 3 | High speed elbow I |

| 4 | Diffuser II |

| 5 | High speed elbow II |

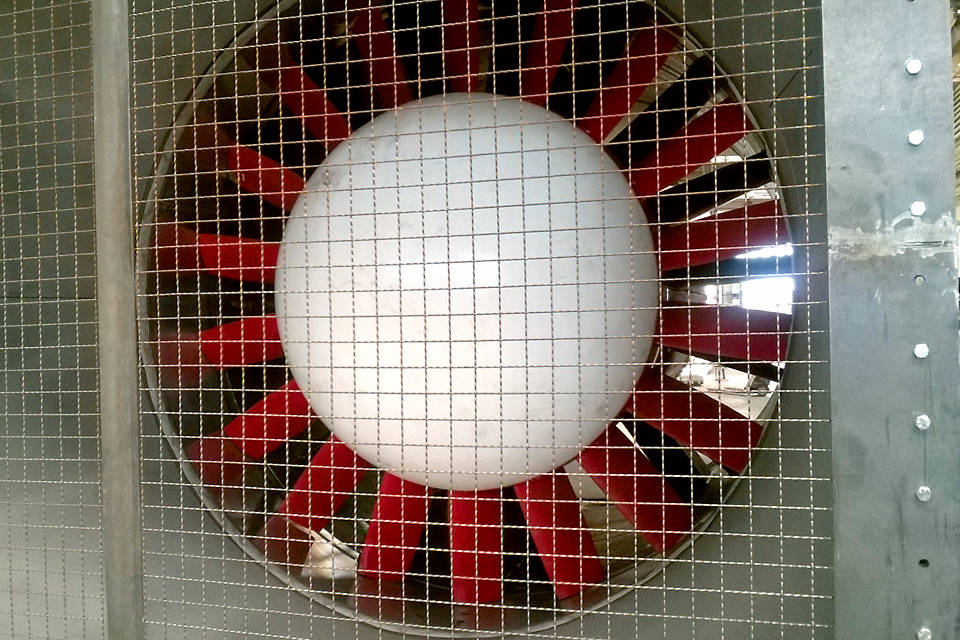

| 6 | Drive unit |

| 7 | Diffuser III |

| 8 | Heat exchanger section |

| 9 | Low speed elbow I |

| 10 | Diffuser IV |

| 11 | Low speed elbow II |

| 12 | Settling chamber |

| 13 | Contraction |

CTO.S.A. STANDARDS

Standard of design of wind tunnels by CTO S.A. is ensure a stable air flow in the test section.

Most of the closed wind tunnels offered by CTO S.A. are traditional tunnels arranged horizontally with one circuit. However, it is possible to make a tunnel of any configuration.

The use of different materials for the construction of tunnels gives you complete design freedom to meet your unique requirements and needs, such as, for example, access restrictions to the laboratory. a low room or supporting pillars of the building.

Advantages of closed type wind tunnels compared to open type tunnels

- lower power demand for a given velocity,

- there may be particles / seeds in the tunnel circuit which do not escape into the room

- the noise in the laboratory is much lower,

- the air movement in the laboratory (air inlets, doors, windows, etc.) does not affect the flow in the wind tunnel,

- the air entering the test section is free of contaminants that may be floating in the laboratory room,

- usually, there is a greater distance between the test section and the fan, preceded by guide vanes, thanks to which the fan blades are not so susceptible to damage caused by detachment of the model or its part,

- the use of a cooling and drying system in the tunnel allows the temperature in the test section to be kept at ± 1°C, making it possible to carry out long-term measurements and tests.

Disadvantages of closed type wind tunnels compared to open type tunnels

- the cost is generally three times higher for a tunnel with the same test section size,

- the space requirement is much greater,

- an increase in air temperature in the tunnel circuit may limit the measurement duration if the tunnel is not cooled,

- additional increase in the cost of implementation in the case of using an air cooling system in the tunnel, the need to provide a technical room for elements of the cooling system,

- more difficult access to the internal parts of the tunnel requiring cleaning after tests with seeds.

CHARACTERISTIC PARAMETERS

Characteristic parameters of closed type wind tunnels designed by CTO S.A.:

- air velocity range – defined by the customer (from 0.1 m / s up),

- turbulence intensity – defined by the customer (from 0.1%),

- contraction coefficient k = 9 or other highest achievable.

The air quality in the test section is correlated with the size of the available room and the possibility of using a sufficiently long section for determining the velocity field or the contraction coefficient, as well as the availability of power in the laboratory.

Contact one of our engineers for more information and a quote.

Prepare the input data that will help us choose the right tunnel.

INPUT DATA

TO BE SPECIFIED BY THE CUSTOMER:

- velocity range in the test section,

- the expected level of turbulence intensity in the test section,

- the size of the largest element that will be tested in the test section,

- climatic conditions in the laboratory,

- power available in the laboratory,

- laboratory dimensions,

- size of the access roads (entrances to the laboratory/room).

Od tradycji

do nowoczesności

Address

ul. Szczecińska 65

80-392 Gdańsk