Wind

tunnel

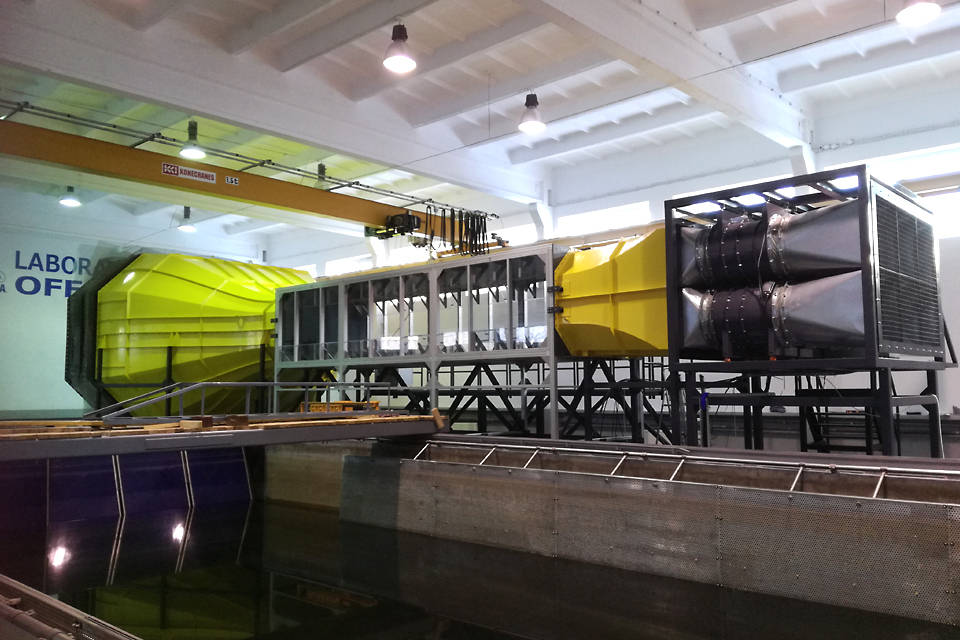

Wind tunnel studies

provide large amounts of reliable aerodynamic data. Wind tunnels are often the fastest, economical and accurate device to conduct aerodynamic research and obtain aerodynamic data to support design decisions. Many industries around the world support aerodynamic research and development, the main focus of which is to conduct wind tunnel experiments according to their needs, capabilities and desires. There is a significant amount of aerodynamic research and development carried out by corporations for civil purposes in the development of aircraft, cars, marine vehicles and architectural structures.

In response to the market demand of CTO S.A. designs, builds and supplies wind tunnels of various types and for various applications, tailored to individual customer requirements, taking into account existing constraints, such as, for example, budget, available space, time and knowledge. In practice, the priority is always to obtain the largest size of the test section with the highest possible velocity of the flowing air with the available means.

WIND TUNNELS

OPEN type

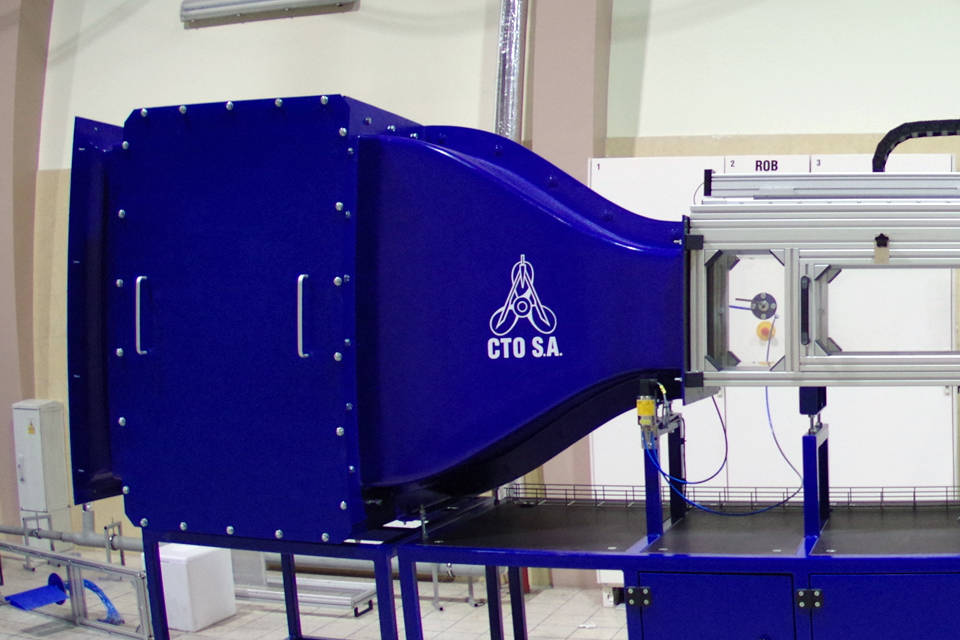

CTO S.A. designs and manufactures custom-made open-loop wind tunnels to exact meet your requirements.

AERODYNAMIC TUNNELS

CLOSED type

In closed-type wind tunnels, a gradually expanding diffuser guides the air back into the contraction so that the air constantly circulates in a closed loop.

TUNNELS

FOR CALIBRATION

CTO S.A. designs and manufactures wind tunnels for the calibration of measuring instruments.

The offered tunnels can be made as open or closed type tunnels.

EDUCATIONAL

TUNNELS

Most of the projects designed by CTO S.A. educational tunnels are open circuit tunnels.

The educational wind tunnel makes it possible to obtain knowledge about the aerodynamics of marine, solid and mobile land and flying objects based on experiments carried out with a model or a prototype.

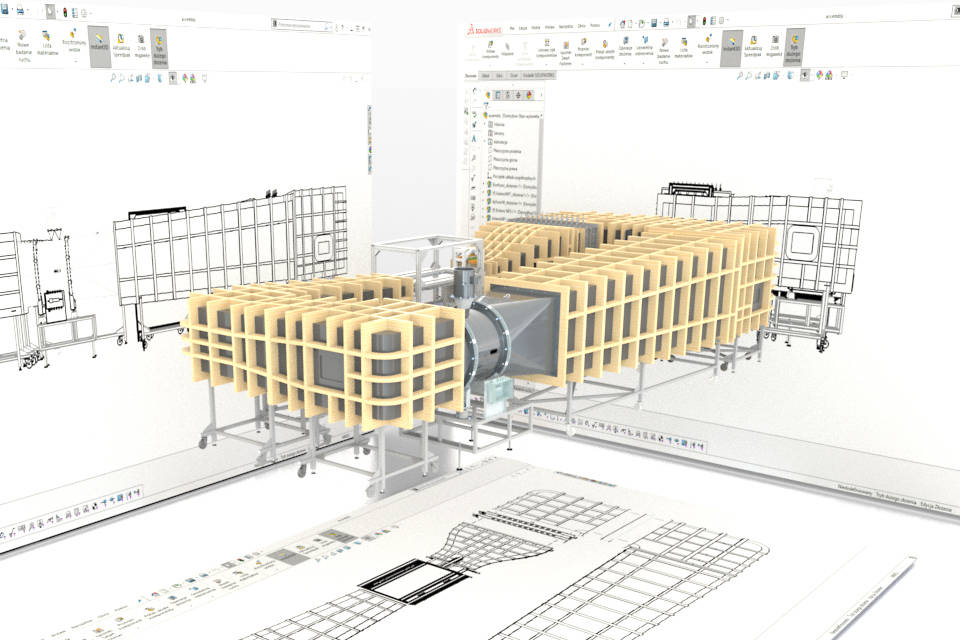

- Defining the dimensions of the test section and the desired flow velocity resulting from the type of tests performed;

- Design of the wind tunnel sections in a way that reduces the risk of flow detachment or undesirable turbulence, while ensuring high quality of the velocity field in the test section;

- Selection of a straightener (honeycomb) and a set of nets of the velocity field setting section, determination of the shape, number and spacing of the flow guide vanes;

- Cooler selection (if used);

- Calculation of pressure losses in individual sections of the wind tunnel and along the entire length of the tunnel;

- Selection of the fan(s),

- CFD analysis of the flow in the test section to verify the correctness of the assumptions.

In the design process, we pay special attention to the construction of the contraction. This section of the wind tunnel is the most critical as it strongly influences the flow quality (velocity, turbulence level, velocity uniformity) in the test section. Contraction curves describe fifth degree polynomials specific for the designed tunnel. After designing the tunnel section, the pressure losses in the wind tunnel are determined, and energy considerations lead to the correct selection of the fan.

More information on the standards of project execution can be found in the OFFER website tab

- advanced control systems,

- Integrated Data Acquisition System (DAS)

- a wide range of measuring devices used in modern model tests.

See catalogue sheets of Wind tunnels

Od tradycji

do nowoczesności

Address

ul. Szczecińska 65

80-392 Gdańsk